Goxing technology

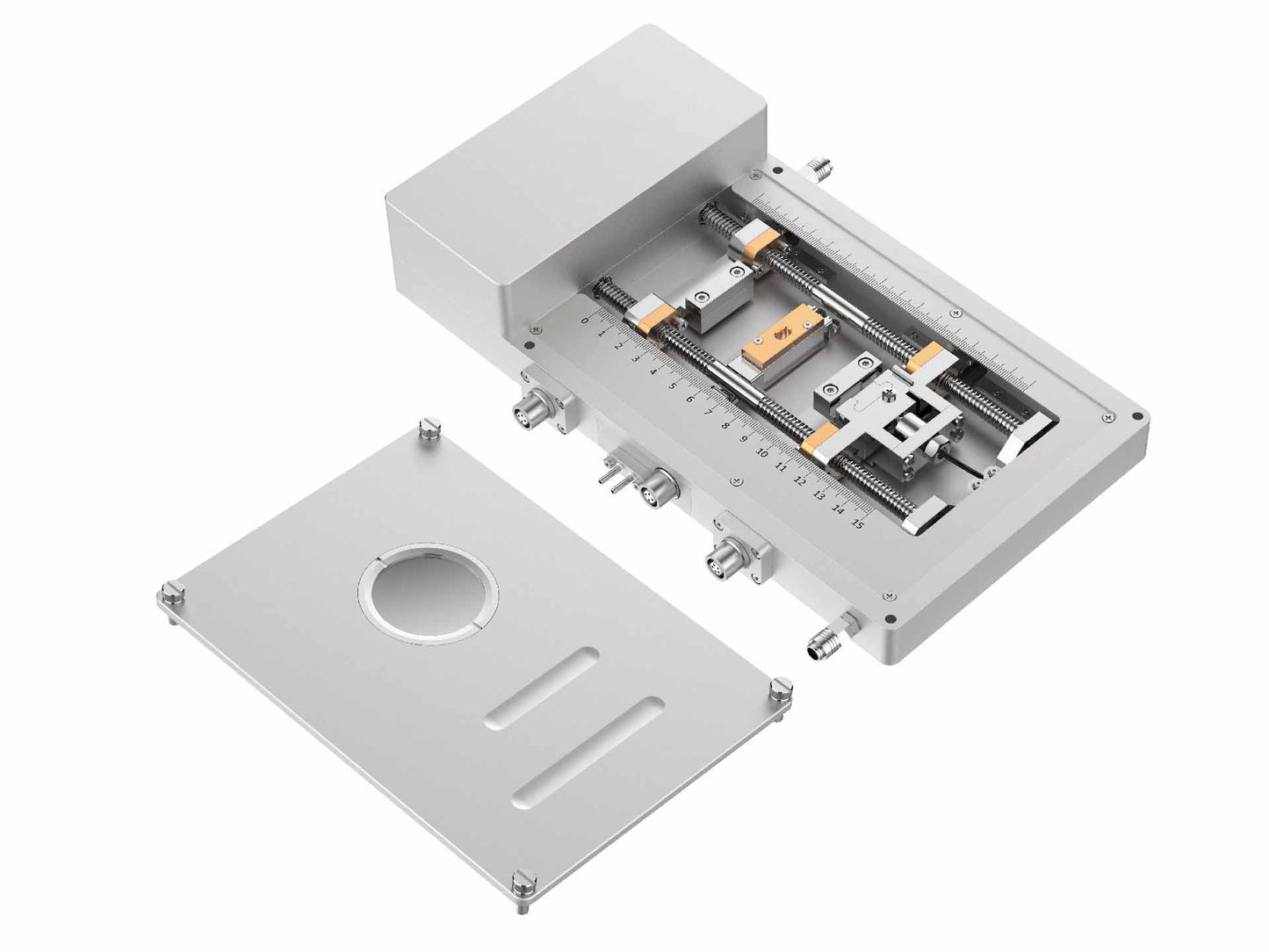

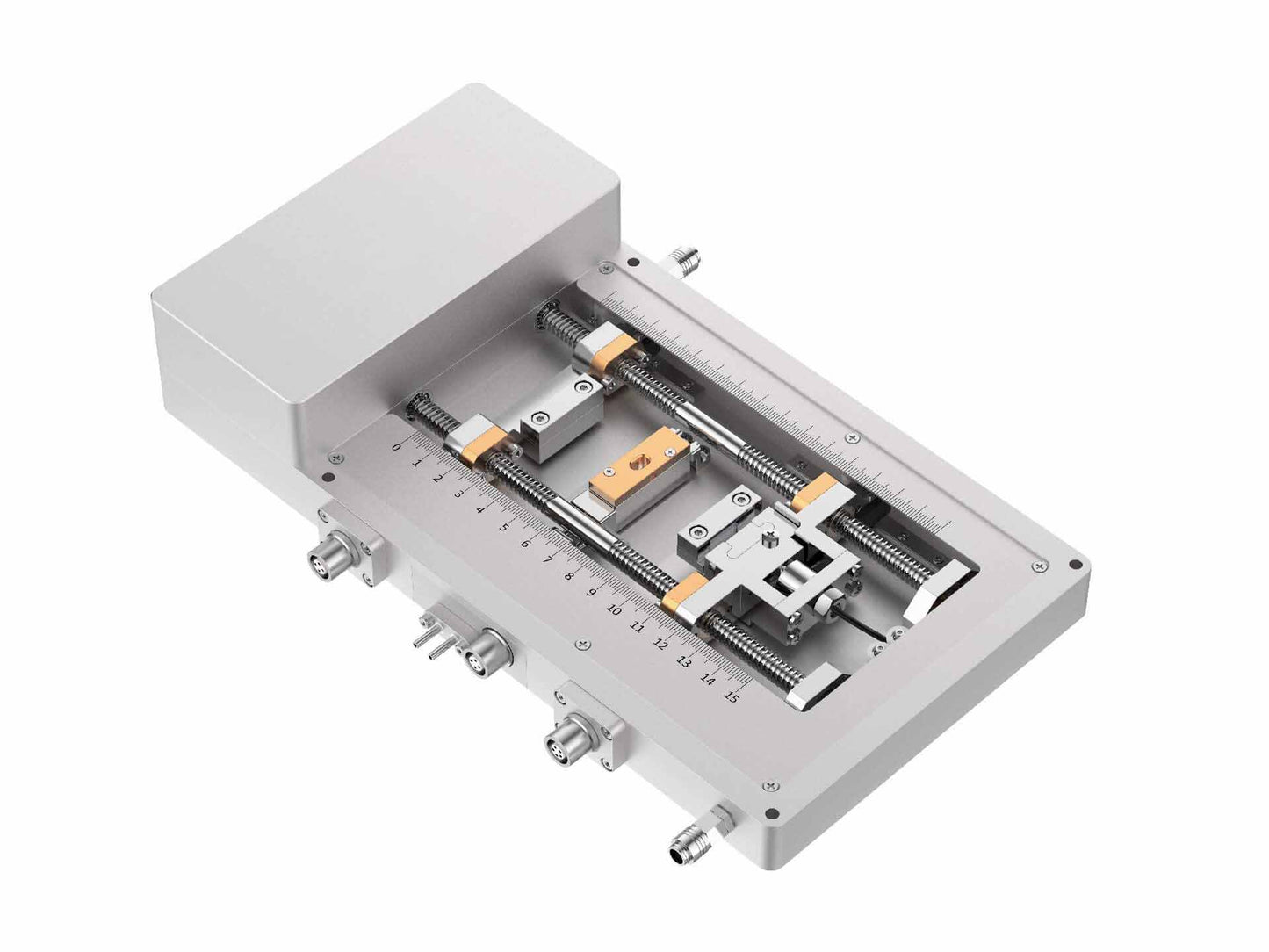

In-situ tensile stage GXTFCH500-200

In-situ tensile stage GXTFCH500-200

Couldn't load pickup availability

• Temperature range: -190℃~200℃

• Temperature stability: ±0.1℃

• Force range: 0~500N

• Mechanical modes: tension, compression, shear, bending

• High-precision temperature control

• Professional temperature control software

• Customization available

Share

-

Product Specification

Model:GXTFCH500-200

1.Cooling and heating method:Liquid nitrogen cooling, resistance heating

2.Temperature control range :﹣190℃~200℃

3.Temperature stability:±0.1℃

4.Temperature control rate:Maximum heating rate: 150℃/min, maximum cooling rate: 40℃/min"

5.Sample stage:Silver; 35mm*12mm

6.Upper window size:φ45mm*1mm

7.Window material:JGS2 quartz glass (transmission wavelength range 220nm~2500nm), manually detachable and replaceable"

8.Distance from upper surface of window to upper surface of sample stage (h):13mm

9.Sample chamber height:5mm

10.Tensile force Range: 20N, 500N; Accuracy: 0.5%F.S.

11.Displacement distance:100mm

12.Stretching speed:0.1~100mm/min

13.Mechanical modes:Tensile, compressive, shear, bending

14.Chamber:Atmosphere

15.Overall dimensions:328mm156mm53mm*

16.Net weight:3.2kg

17.Basic configuration:TCS, in-situ stretching stage1, temperature controller1, cooling controller1, liquid nitrogen tank1, circulating water machine1, mechanical controller1, connecting wires, pipelines, accessories, etc.

18.Optional:Adapter plate/custom liquid nitrogen tank/custom circulating water machine/vacuum system/computer host/custom temperature control software, etc.

-

Configuration List

Software| Stage| Temp Controller| Cooling Controller| LN2 Dewar| Chiller| Accessories

Optional: Adapter plate / Custom LN2 dewar / Custom chiller / Vacuum system / Custom Probe / Custom Probe Interface/

PC / Custom temp software, etc